Well, 12 Hours have past since the negative was pored and it was time to see how it went.

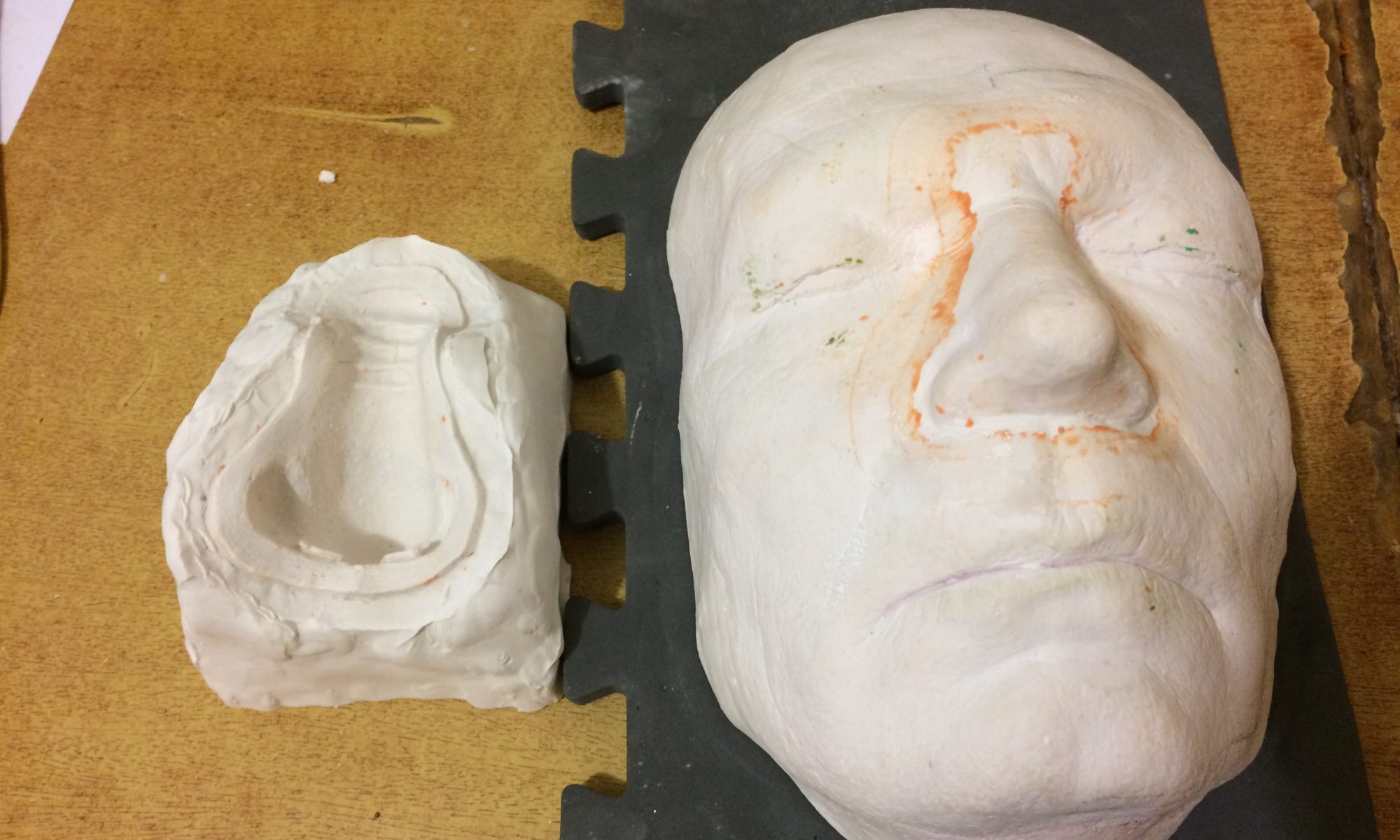

The 2 Pieces came apart very easily so the vaseline worked very well as a barrier for the hydrocal – although as we will see it did leave light brush marks in the resulting cast.

As you can see, there is some cleanup work to do on the pieces to remove the plasticine.

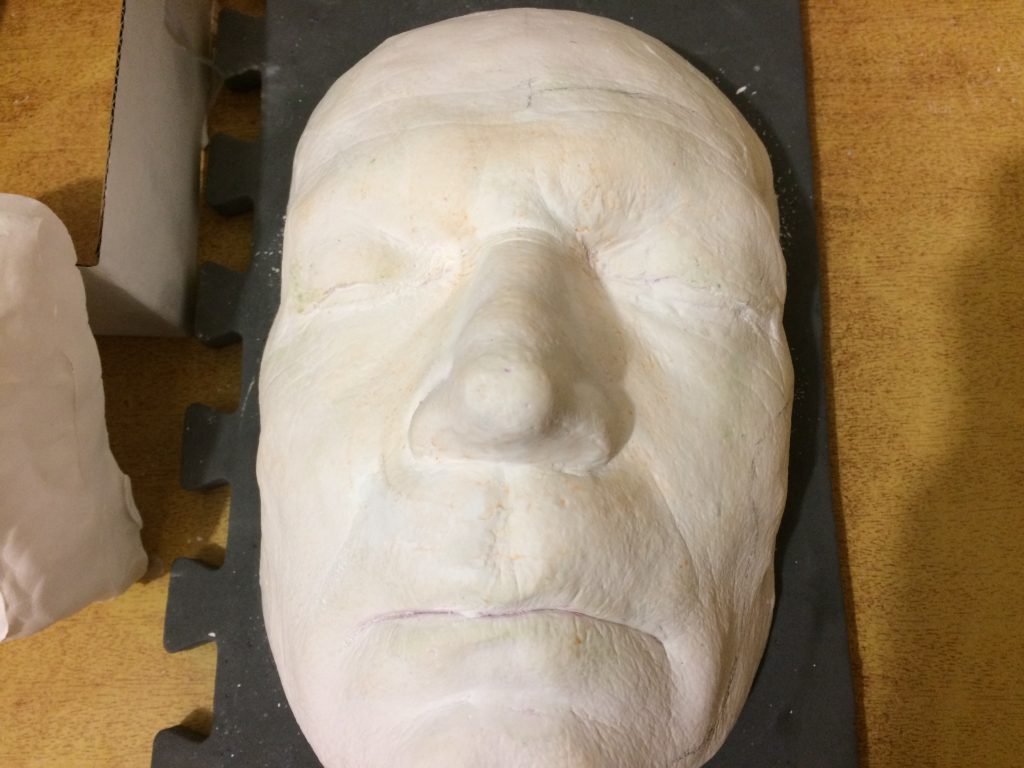

Closeup of the Negative mold piece. The nose pores are very clear (which is excellent) but as mentioned, you can see the light brush strokes. This shouldn’t be a big problem as the platsil gel-00 is translucent white and once pigmented and adhered to the skin they should be almost invisible.

So on with the cleaning. Iso Alcohol was used to dissolve the Plasticine although a small amount of the colorant in the Plasticine did stain the hydrocal – but its just color.

Now I will leave it a couple of days in a warm dry environment to ensure the hydrocal is fully cured before we get onto the REALLY fun part – Casting my first Silicon prosthetic … YAY!